IMTS 2018 Booth Traffic Up 75%!

Hamar Laser’s new spindle alignment lasers and record attendance helped us have one of our best shows in 10 years

By Rod Hamar, President & CEO, Hamar Laser Instruments, Inc.

Hamar Laser has been exhibiting at the International Manufacturing Technology Show (IMTS) for many years and this year’s show was definitely one of our best.

We enjoyed catching up with many of our customers and met a lot of prospective customers who are looking for easier and faster ways to solve a variety of alignment problems. Naturally, we’ve been busy providing information and quotations ever since the show!

Also lending a hand at the show was Guy Laverty, our Midwest Territory Manager for our extensive line of Geometry Products, and Ron Sullivan, our Brand and Distribution Manager for our X Series™ Shaft Alignment Products.

A 30-year industry veteran, Ron Sullivan said the show was massive and overwhelming: “It really blew my mind just how many companies were there, and how much machinery and technology was on display,” he said.

Held in McCormack Place in Chicago from September 10-15, the exhibition was the largest IMTS ever, with more than 2,563 international exhibitors and 129,415 attendees in a vast 1.4 million-square-foot venue. Mark Albert, editorial director of Modern Machine Shop, dubbed it “North America’s greatest machine tool show.”

IMTS’s PDA lead retrieval system helped us respond quickly to leads. It pushed them online where they could be downloaded each day and processed by our support team: Amy Smith-McKeown, our Customer Support Manager and Teri Carlisle, our Training Coordinator.

Enhanced Spindle Alignment

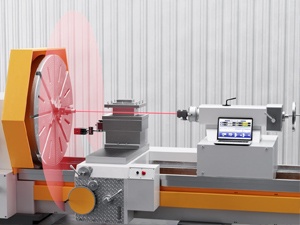

We enjoyed demonstrating our new L-702 and L-702SP Spindle Alignment Lasers at the show and were happy to hear very positive feedback.

The new L-702 lasers add a compact squareness-checking capability to our standard spindle alignment laser. We designed them to fit into most lathes, even small ones, but also into multi-turn milling centers, a segment of machine tools that we think is underserved. As is our way, we made the L-702 and L-702SP as accurate as we can and think they will be the most accurate in the market.

During his more than 40 years of machine tool experience, Guy Laverty has heard from many people who call him after crashing a lathe. “They need to be able to check both the axis of rotation of the lathe and the squareness of the slide,” he said. “These compact new lasers will be great for quickly checking CNC lathes, multi-turn machines and very large manual lathes.”

Measuring Machines Vs. Measuring Parts

As usual, our exhibit was in the Quality Assurance Pavilion (booth 135436), located among many large, well-known exhibitors offering part measurement, testing and Q&A products and services which helped bring traffic by our booth. As Guy put it, “We got a lot of steady traffic, all day, each day.”

For the last 10 or so years that I have attended this show, I am often stuck by an odd disconnect: Nearly all of the companies exhibiting in the QA Pavilion at this huge show are focused on measuring the finished parts after they have been manufactured, but very few of them focus on measuring the machines before they make the parts. We’re one of the few, the proud and the brave! Okay, maybe brave doesn’t apply, but few and proud!

So our biggest challenge is to help people understand that if you consistently measure and align your machines as part of a good preventative maintenance program before you start finding part quality problems, then your Q&A results will be much improved! This is just one reason why a relatively small investment in laser alignment can quickly pay for itself. Of course, you have to invest time and effort into consistently using these kinds of tools or else nothing will improve.

For our customers that really embrace this way of maintaining good machine alignment, they find that part quality does indeed improve and scrap rates fall. It doesn’t hurt that the speed of our lasers also helps to reduce downtime, especially after a machine crash, but also for the periodic PM checks.

International Space Station

Many customers stopped by our booth to say “hello” in person and shared some very kind comments about the various Hamar Laser systems they are using. It’s always great to hear how our products really do help our customers, and it’s such a compliment to hear how our lasers have become like a “Kleenex” or a “Xerox” where we sometimes hear people say, “You gotta Hamar that machine…!”

We also got reacquainted with some early customers. We were fledgling industry “pioneers” when my father, Martin Hamar, started the company in 1967, so some of these relationships go way back. Ron heard somebody say loudly, “Hamar Laser! I’m glad to see you guys are still around!” It was Jan Christianson of Flex-Cable, and Dan Cress of Andrews University.

As Ron put it, these gentlemen are real “rocket scientists,” very smart, well-educated engineers. Jan was working for a company many years ago that designed and built the custom CNC drilling system that Lockheed used to assemble solar panels for the International Space Station, or ISS. Back then, Jan had used an early design Hamar Laser system to check the straightness, flatness and squareness of the machine to the high tolerances they required.

The ISS is powered by an extensive solar array and it’s satisfying to know we played a part in that historic project!

Auto Accessories Manufacturing

It was good to see so many prospective customers navigate to our booth with a show guide or a phone app in their hands. These folks didn’t just stop by. They had specifically sought us out after doing some careful show prep, sometimes through our digital showroom, IMTS.com.

One group like this was from a large manufacturer of automotive accessories in Mexico. The company uses a very large stamping press to manufacture critical parts, but doesn’t yet have an in-house capability for checking and aligning its machinery. After some drive mechanism failures they had outsourced this work but weren’t satisfied with the results. Having in-house measuring capabilities will let them tackle alignment issues quickly and without having to wait to get on the contractor’s schedule.

They were very interested in our L-743 Ultra-Precision Triple Scan® Laser for roll-type machinery for a variety of measurements, including machine roll parallelism, plus flatness and leveling*. The L-743 is our flagship alignment tool. As Guy said, “The L-743 is a wonderful tool. It’s extremely accurate, powerful and versatile, and no one else has an alignment product that can do what this one does.”

*Our L-742 Ultra-Precision Dual Scan® and L-732 Precision Dual Scan® lasers are often used for roll alignment applications, but the L-743 can be used for roll alignment with additional capabilities to meet some companies’ specific requirements.

Miles For Manufacturing 5K

And finally, we often heard visitors saying they were concerned about the “great brain drain” that is making it extremely hard for companies to hire qualified younger people for jobs in manufacturing (a problem we face at Hamar, too). So we’re really proud that Ron represented Hamar Laser in the “Miles for Manufacturing 5K” fundraiser that was held during the show.

Miles for Manufacturing supports educational efforts that will help to fill the employee pipeline, so that down the road the manufacturing sector has a viable pool of well-trained and educated candidates to fill positions that are being vacated as experienced workers age and exit the workforce.

Thanks to caring people like Ron, the event raised $28,000, exceeding the organizers’ goal by $3,000. Enthused by the 5K, Ron said he will be participating in other Miles for Manufacturing events “because it’s a good cause and a good way for us to give back to an industry that provides great careers for all of us.”

Looking Forward To 2020!

On that hopeful note, I’d just like to say that after this year’s exciting show we’re looking forward to IMTS 2020. In the meantime, please visit the Hamar Laser website if you want more information about us, and get in touch if we can help!